Product Description

In the field of sugar production, a rotary vacuum filter is an essential piece of key equipment for achieving efficient separation of solids and liquids in sugar juice. Whether it involves processing sugarcane for sugar production, using sugar beets for industrial sugar production, extracting residual sugar from mud juice, processing filter cakes produced by the carbonation process, or purifying green juice to improve quality, all these processes rely on this equipment for operation.

Working Principle and Application Scope of rotary vacuum filter in sugar industry

The rotary drum vacuum filter is a type of continuous vacuum filter. Its filter sectors are made of high-strength polypropylene, with a reasonable structural design that ensures sturdiness and durability. It can be widely applied in industries such as alkali manufacturing, mining, coal slime dewatering, papermaking, food processing, pharmaceutical production, and metallurgical sludge dewatering.

Structure and Working Principle of the Rotary Vacuum Filter

It consists of a horizontal rotating drum with holes on its wall. A supporting plate and filter cloth are laid on the drum surface to form the filtering surface. The space under the filtering surface is divided into several separate fan-shaped chambers, each of which is connected to a distribution valve via a conduit.

As the drum rotates one full cycle, each filter chamber is alternately connected to the vacuum system and the compressed air system through the distribution valve, sequentially completing operations such as filtration, washing, drying, slag discharge, and filter cloth regeneration. On the entire filtering surface of the drum:

The filtration zone accounts for approximately 1/3 of the circumference;

The slag washing and drying zone accounts for 1/2 of the circumference;

The slag discharge zone accounts for 1/6 of the circumference;

There are transition sections between these zones.

During filtration, the lower part of the rotating drum is immersed in the suspension and rotates. The filter chambers submerged in the suspension are connected to the vacuum system: the filtrate is sucked out of the filter, while solid particles are adsorbed on the filtering surface to form filter residue. After rotating out of the suspension with the drum, the liquid contained in the filter residue is continuously sucked away. When it is necessary to remove the residual filtrate in the filter residue, washing water can be sprayed when the filter chamber rotates to the upper part of the drum. At this time, the filter chamber is connected to another vacuum system, and the washing water penetrates the slag layer to displace the residual filtrate between the particles. The filtrate is sucked into the filter chamber and discharged separately, followed by the removal of the dried filter residue.

1. Core components and materials

Drum body: 316L stainless steel precision casting, roundness error ± 0.05mm, dynamic balance G0.5 level, surface laser cladding 3-5mm ceramic layer, life extended by 50% compared to electroplating.

Filtering system: conventional PP filament filter cloth; High end models will use graphene composite filter materials for mass production in 2025.

Vacuum distribution head: Double sealed design, vacuum degree -0.08~-0.095MPa, distribution accuracy ± 0.5%; Compared to traditional equipment, the moisture content in the filter cake can be reduced by 3-5 percentage points, making subsequent processing of the filter cake more convenient.

2. Automated control system

Standard Siemens S7-1200 PLC+10 inch touch screen, supports timed/constant pressure difference self-cleaning, real-time monitoring of filtration speed, filter cake thickness and other parameters.

High end models are equipped with IoT module, remote operation and maintenance+fault warning (accuracy ≥ 92%), edge computing optimization cycle, and energy consumption is reduced by 13%.

Reserved DP interface, which can be connected to the MES system of the sugar factory to achieve full process data traceability.

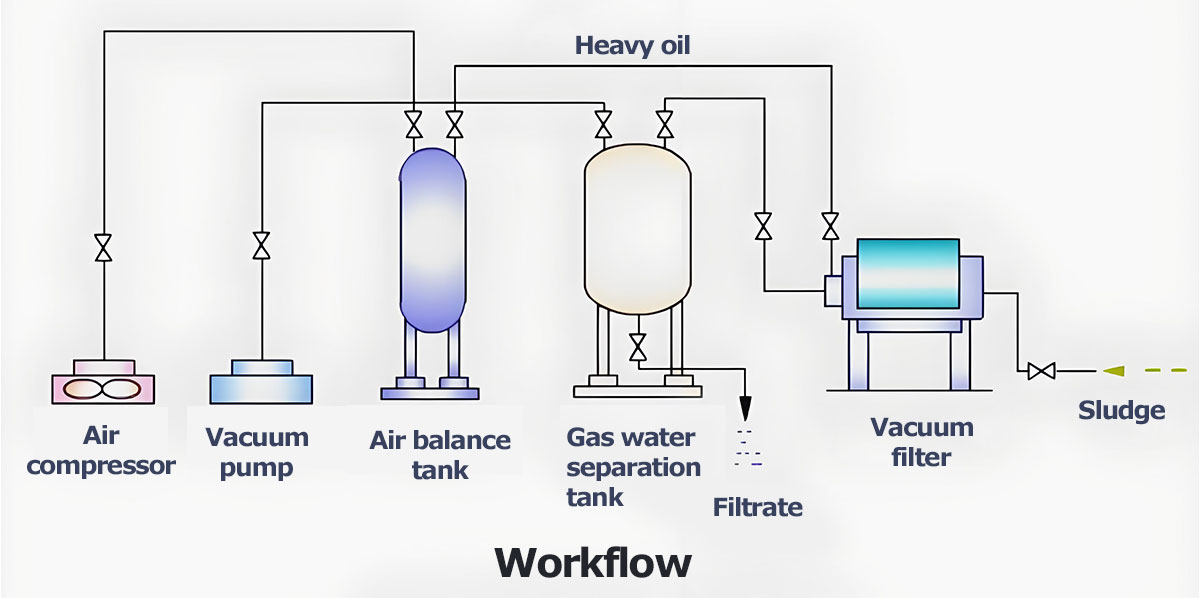

Workflow and process adaptability

1. Continuous filtration cycle

Feed adsorption: The rotary drum immerses 25% -35% of the mud juice and forms a 3-8mm filter cake under vacuum;

Drying and washing: high-pressure spray (0.3-0.5MPa) countercurrent sugar washing (efficiency ≥ 98%), secondary drying to a moisture content of 25% -30%;

Unloading regeneration: 15 ° -45 ° scraper unloading+0.4-0.6MPa back blowing filter cloth, 20-40 seconds/cycle.

2. Process optimization

Carbonation method: equipped with a 5-10mm pre coating system, with a filtration speed of 2-4m ³/(m ² · h) and a 50% efficiency improvement;

Sulfuric acid method: Optimize vacuum curve, clear juice turbidity ≤ 50NTU;

Energy saving: Driven by a variable frequency motor, energy consumption is reduced by 18-22%, saving 12000 kWh of electricity per year (20 hours of daily operation).

The Core competitive advantages of rotary vacuum filter in sugar industry

Continuous operation capability

24-hour uninterrupted operation, annual effective operation time ≥ 8000 hours, 3-4 times higher efficiency than intermittent plate and frame filter press.

Cost economy

No need to build sedimentation tanks, saving about 40% of soil construction investment. The service life of filter cloth can reach 6-12 months, and the cost of consumable replacement is 15% lower than similar equipment.

Environmental adaptability

It operates stably in humid and foggy areas (such as sugarcane production areas in southern China), and there is no risk of condensation in the vacuum system at low temperatures (-5 ℃).

Rotary vacuum filter in sugar industry manufacturer

The numerous rotary vacuum filters in the sugar industry are not just "filtration tools", but key equipment that cannot be separated from the purification of sludge to the processing of filter cake. He can not only capture impurities in the sugar juice, making the subsequent crystallized sugar products of higher quality, but also improve efficiency and save costs for sugar factories through continuous operation, especially suitable for the large-scale production needs of medium and large sugar factories.

With the increasing demand for energy conservation and intelligence in the sugar industry, this equipment can also be upgraded, from more durable filter materials to remote operation and maintenance systems, all of which are helping sugar factories reduce energy consumption and trouble. In the future, it will continue to move towards a lower carbon and smarter direction, playing an important role in the sugar production line and providing reliable support for sugar factories to ensure quality and control costs.

Hot Tags: