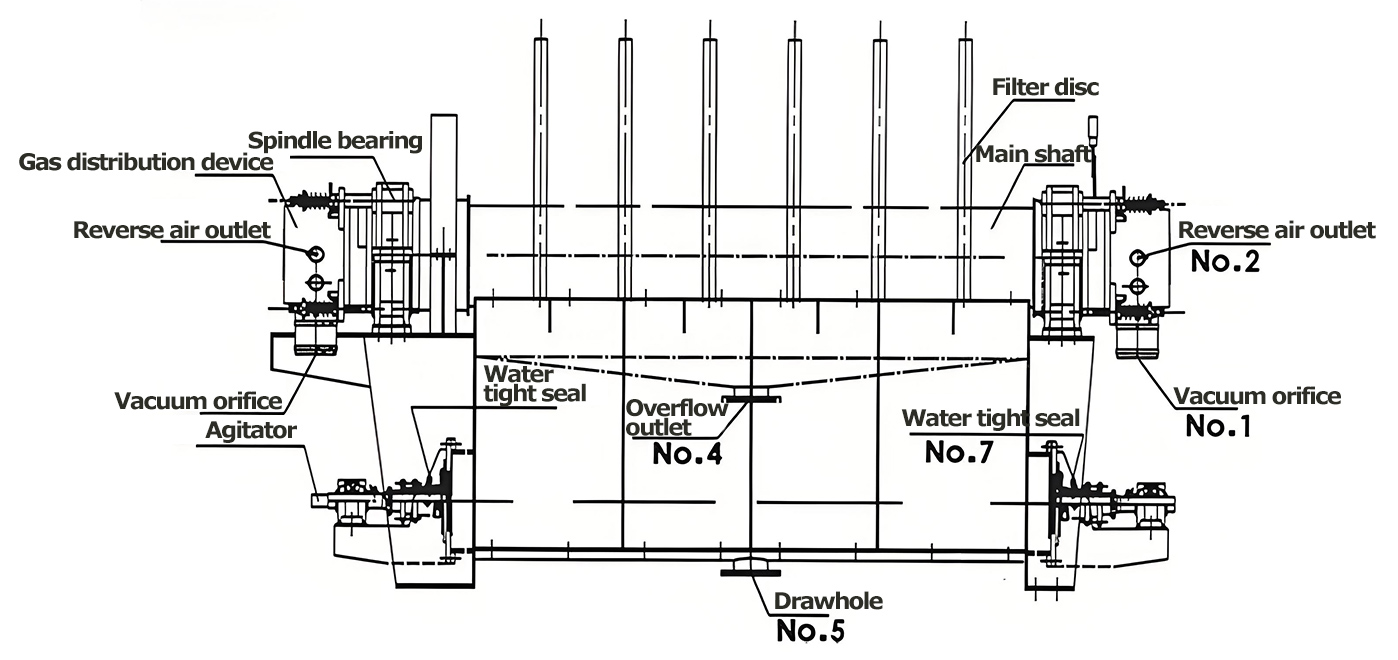

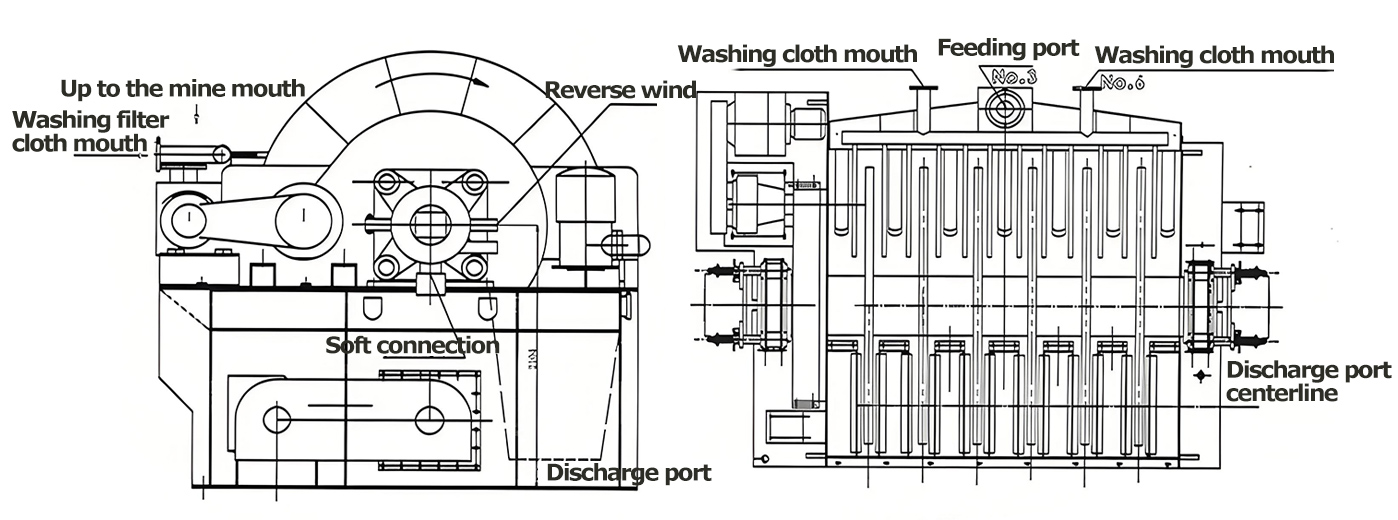

The vacuum ceramic filter is a device integrating electromechanics, microporous ceramics and ultrasonic technology, which mainly realizes solid-liquid separation by virtue of vacuum suction and capillary action. It is similar to the disc vacuum filter in terms of external structure, but its technical core has achieved a breakthrough upgrade. The device adopts a modular integrated design and is mainly composed of eight functional units: a rotating drive rotor system, an intelligent variable-frequency stirring device, an adaptive material hanging component, a U-shaped slurry circulation tank, a multi-channel vacuum distributor, a group of microporous ceramic filter discs, a closed-loop water treatment system, and an intelligent control platform based on the industrial material network.

Working Principle:

During operation, the ceramic filter plates in the slurry tank utilize the suction force generated by vacuum and their own capillary action to cause solid particles in the slurry to adhere to the filter plate surface, gradually accumulating to form green tea cakes. The filtrate then passes through the filter plates into the distribution valve and flows into the drain tank. Once the filter cake is formed, it is removed and discharged by a specialized scraper. After completing the unloading process, the filter plates undergo a backwashing procedure. Industrial water or filtrate is introduced into the ceramic plates via the distribution valve, rinsing from the inside out. Additionally, ultrasonic waves and low-concentration acid solutions are periodically used in combination for mixed cleaning to ensure the ceramic plates maintain optimal filtration performance at all times.

Core Strengths

High Efficiency and Energy Saving

Compared to traditional filtration devices, this product reduces energy consumption by over 90%, significantly lowering operational costs.

Compact Design

A senior manufacturing enterprise with professional design, R&D and manufacturing teams.

Washable Filter Cake

Some models are specially equipped with a filter cake washing function, making them highly suitable for materials requiring washing, and fully meeting diverse process requirements.

Model parameters

| Model | Filter area (㎡) | Filter disk /ring | Number of filter plates (pieces) | Tank volume (m ³) | Installed power (kW) | Operating power (kW) | Host size (L × W × H, m) | Vacuum degree (MPa) | Water consumption (m ³/h) | Equipment weight (t) |

| TC-1 | 1 | 1 | 12 | 0.21 | 3.5 | 2 | 1.6×1.4×1.5 | -0.09~-0.095 | 0.2 | 1 |

| TC-4 | 2 | 2 | 24 | 1 | 7 | 3 | 2.4×2.5×2.1 | -0.09~-0.095 | 1.2 | 3 |

| TC-6 | 2 | 2 | 24 | 1.2 | 7 | 6 | 2.4×2.9×2.5 | -0.09~-0.095 | 1.2 | 3 |

| TC-9 | 3 | 3 | 36 | 1.7 | 9 | 7 | 2.7×2.9×2.5 | -0.09~-0.095 | 1.8 | 3.5 |

| TC-12 | 4 | 4 | 48 | 2.2 | 11 | 7.5 | 3.0×2.9×2.5 | -0.09~-0.095 | 2.4 | 4 |

| TC-15 | 5 | 5 | 60 | 2.7 | 11.5 | 8 | 3.3×3.0×2.5 | -0.09~-0.095 | 3 | 4.5 |

| TC-21 | 7 | 7 | 84 | 4 | 13.5 | 9 | 4.6×3.0×2.6 | -0.09~-0.095 | 4.5 | 5 |

| TC-24 | 8 | 8 | 96 | 4.5 | 16.5 | 10.5 | 4.9×3.0×2.6 | -0.09~-0.095 | 5 | 9 |

| TC-27 | 9 | 9 | 108 | 5 | 17 | 11 | 5.2×3.0×2.6 | -0.09~-0.095 | 5.5 | 9.5 |

| TC-30 | 10 | 10 | 120 | 5.5 | 17.5 | 11.5 | 5.5×3.0×2.6 | -0.09~-0.095 | - | 10 |

Product Features:

Superior Vacuum Performance: Capable of creating a vacuum environment ranging from 0.09 to 0.098 MPa, significantly reducing moisture content in the filter cake under these conditions.

Ceramic Filter Plates with Superior Performance: Featuring high skeleton density, strong membrane layers, wear resistance, pressure resistance, corrosion resistance, high porosity, high production capacity, high filtration precision, low vacuum energy consumption, multiple regeneration methods, and a long service life.

High Automation Level: Typically employs PLC and microcomputer-controlled automatic valves for control, enabling fully automated completion of the entire process including feeding, filtration, unloading, and cleaning, significantly reducing manual labor intensity.

Product Applications:

This product has extremely widespread applications across numerous industries, including mining, metallurgy, chemicals, and environmental protection. In the mining sector, it plays an outstanding role in the dewatering treatment of concentrates and tailings from various types of ores, including non-ferrous metals, rare metals, ferrous metals, and non-metallic minerals. In the chemical industry, it efficiently handles the dewatering of oxides, electrolytic slag, leaching residue, and furnace slag. In the environmental protection sector, it effectively addresses tasks such as wastewater sludge treatment and waste acid processing. Additionally, it demonstrates strong adaptability to material fineness, capable of processing materials with a fineness range of -200 to -450 mesh and various ultra-fine materials.

Vacuum Ceramic Filter Manufacturer

As a professional manufacturer of vacuum ceramic filters, YiNuo Machinery has always adhered to the spirit of craftsmanship and deepened its technical expertise. Relying on a mature process system, strict quality control standards, and large-scale production capabilities, we ensure that our equipment has excellent performance and stable operation while providing customers with highly competitive pricing solutions.

Choosing YiNuo Machinery means choosing not only a set of efficient and energy-saving process equipment, but also a long-term and stable technical cooperation guarantee. We will accurately match the appropriate machine type based on your actual working conditions and provide cost-effective equipment solutions to jointly improve production efficiency and create a sustainable future.

Hot Tags: