In the industrial field, separating solid-liquid mixtures is a crucial step, and continuous rotary vacuum filter, as an efficient separation equipment, are widely used in multiple industries due to their own advantages. So what exactly is it, a device? What are the characteristics and application value?

Definition:

Continuous rotary vacuum filter is a type of filter that uses vacuum suction as the filtering power to achieve solid-liquid separation through filter cloth or mesh, and it can also operate continuously and efficiently. The continuous rotary vacuum filter can continuously process a large amount of suspension in an uninterrupted working state, intercept solid particles, and extract liquid through the filter medium to achieve efficient solid-liquid separation. It is widely used in many industrial fields such as chemical, food, pharmaceutical, mining, etc.

Working Principle

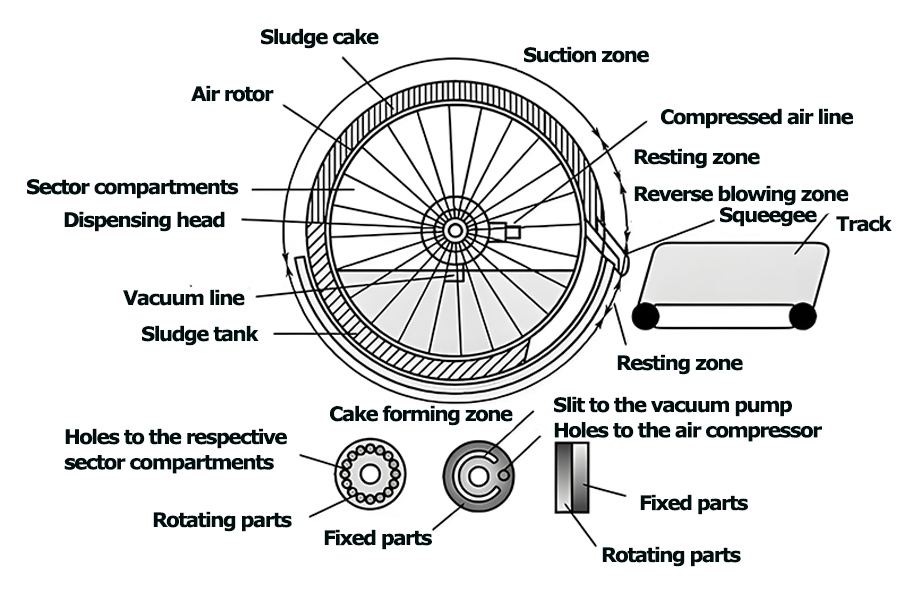

The working principle of the continuous rotary drum filter is based on the vacuum adsorption and the interception effect of the filter medium. Its entire working process can be divided into four consecutive stages:

Initial filtration stage

The suspension is evenly spread on the surface of the filter medium through the feeding system. At this time, the driving device drives the drum to rotate at low speed, maintaining a stable vacuum environment inside the drum. Under the action of pressure difference, the liquid phase quickly penetrates the filter medium and enters the internal channel of the drum, and is discharged through the vacuum system; Solid particles are trapped and form an initial filter cake layer on the surface.

Dynamic washing stage

When the filter cake enters the washing area with the drum, a dedicated spray device is activated to spray the washing solution onto the surface of the filter cake at a specific angle and pressure. Through infiltration, residual mother liquor and soluble impurities in the filter cake voids are effectively replaced, significantly improving the purity of the product.

Deep dehydration stage

The washed filter cake enters the suction drying zone, and the vacuum system switches to the enhanced adsorption mode. At this time, the vacuum degree inside the drum is increased to a higher level, and with the capillary action of the filtering medium, the residual free water and bound water inside the filter cake are continuously extracted, which can reduce the moisture content of the filter cake.

Automatic unloading stage

When the filter cake reaches the unloading area, the scraper device maintains a precise gap with the surface of the drum and mechanically peels off the dried filter cake. After unloading, the filter medium randomly enters the backwash cleaning area and is blown back with compressed air to remove residual fine particles, restore medium permeability, and prepare for the next cycle.

The core advantage of the continuous rotary filter lies in its continuous design: during the rotation of the drum, each functional area operates synchronously, forming a closed-loop process of filtration washing dehydration unloading. This combination of spatial partitioning and continuous operation over time achieves efficient processing capabilities per unit time, making it particularly suitable for large-scale industrial production scenarios.

Construction composition:

The continuous rotary vacuum filter is mainly composed of the following key parts, which work together to ensure the stable operation and efficient filtration of the equipment.

Drum: As the core component, it adopts a cylindrical design, covered with filter cloth or mesh on the surface, and divided into multiple independent fan-shaped chambers inside, which are respectively connected to the vacuum machine drainage system and achieve continuous rotation through a driving device.

Filter media: The filter cloth material is diverse, with adjustable pore size. The filter screen is mostly woven with metal wire, suitable for high temperature or high-precision filtration scenarios, used to intercept solid particles and form a filter cake.

Vacuum system: consisting of a vacuum pump, pipelines, and regulating valves, it creates negative pressure by sucking air from the drum, providing power for liquid filtration and ensuring that the liquid phase penetrates the medium into the drum.

Transmission device: It includes a motor, a reducer, and a coupling. After the motor is reduced in speed, it drives the drum to rotate at low speed through the coupling, ensuring the orderly connection of each filtration stage (filtration, washing, drying, unloading).

Liquid tank: located below or on the side of the drum, with a built-in mixing device to maintain uniform suspension concentration, prevent solid particle settling, and ensure feeding stability.

Washing device: It consists of a storage tank, a pump, and a nozzle. The nozzle is installed above or on the side of the drum to evenly spray washing solution to replace the mother liquor and impurities in the pores of the filter cake, and improve the purity of the product.

Unloading device: including a scraper and a conveyor. The scraper is located below the drum to strip and dry the filter cake, which is then transported to the subsequent processing steps by the conveyor to achieve simultaneous backwashing and cleaning of the filter cloth.

Control system: With PLC as the core, integrated sensors and instruments, real-time monitoring and adjustment of parameters such as speed, vacuum degree, washing volume, etc., to achieve automated operation, fault warning, and process optimization.

Advantages analysis of rotary continuous filter

Continuous operation, high efficiency

Seamless connection of filtration, washing, dehydration, and unloading is achieved through continuous rotation of the drum, avoiding the efficiency loss caused by frequent start stop of intermittent equipment and significantly shortening the production cycle. It is more suitable for large-scale continuous production scenarios.

High degree of automation

This equipment is usually equipped with a complete control system, which can dynamically adjust the core data of parameters such as drum speed, vacuum degree, and detergent dosage, reducing manual operation errors, lowering the labor intensity of operators, and improving the stability and accuracy of operations.

Good filtration effect

Vacuum negative pressure drives the liquid phase to quickly penetrate the filter medium, resulting in more thorough dehydration of the filter cake. Combined with countercurrent washing design, it efficiently removes the mother liquor and soluble impurities, significantly improving the purity of the filter cake and meeting the high cleanliness requirements of multiple industries for products.

Widely applicable

The material and aperture of the filter cloth/screen can be flexibly selected and adjusted according to parameters such as speed and vacuum degree, covering a wide range of material systems from low concentration fine particles to high concentration coarse particles, and applied in multiple fields such as chemical, food, pharmaceutical, and mining.

Application of continuous rotary vacuum filter in Sugar Industry:

1. Sugar juice clarification: Processing the mixed juice (containing impurities such as sediment and protein) after pressing, separating the clarified sugar juice and sediment through vacuum adsorption, washing and drying the filter cake, and discharging it to provide high-purity sugar juice for subsequent processes.

2. Sugar paste filtration: Separate the mother liquor and sucrose crystals from the evaporated and crystallized sugar paste, wash the residual mother liquor on the surface of the crystals, improve the purity of the finished sugar, and after drying, unload the cake to produce qualified sugar.

3. Extended application: Taking into account the treatment of by-products such as waste honey, recycling useful ingredients, and improving resource utilization efficiency.

This equipment has become a key equipment for impurity removal, crystal purification, and resource recovery in the sugar industry due to its continuous operation, efficient separation, and deep washing capabilities.

Troubleshooting:

1. Decreased filtering speed:

Possible reasons: clogged filter cloth/screen, insufficient vacuum degree; The concentration/viscosity of the feed solution is too high, and the drum speed is too fast.

Exclusion method: First, clean or replace the clogged filter cloth; Check the sealing of the vacuum pump and pipelines, and repair any air leaks; Then dilute the material solution or adjust the process to reduce viscosity; Reduce the rotational speed of the drum.

2. High moisture content of filter cake:

Possible reasons: Insufficient vacuum degree; Short drying time; The filter cloth is damaged; Excessive detergent.

Exclusion method: Increase the vacuum degree inside the drum, reduce the drum speed appropriately, and extend the residence time of the filter cake in the suction drying stage; Check if the filter cloth and screen are damaged, and replace them promptly to reduce the amount of detergent used.

3. Difficulty unloading cakes:

Possible reasons: The filter cake is too thick or hard, and the gap between the scraper and the drum surface is too large or too small; The filter cloth is aging.

Exclusion method: If the filter cake is too thick or hard, you can increase the drum speed appropriately, reduce the thickness of the filter cake, or adjust the concentration and vacuum degree of the feed solution; Adjust the gap between the scraper and the surface of the drum to maintain it within an appropriate range. If the filter cloth ages, it should be replaced in a timely manner and a filter cloth and screen that match the properties of the material should be selected.

4. Abnormal vibration or noise of equipment:

Possible reasons: Unbalanced drum; The transmission device has zero wear or looseness; Bearing malfunction, low liquid level in the material tank.

Exclusion method: Conduct balance testing and calibration on the drum to ensure its balance during rotation; Check the motor, reducer, coupling and other components of the transmission device, replace worn parts and tighten the transmission components; Check the lubrication condition of the bearings, add lubricant or replace according to the situation; Adjust the material level in the liquid tank to maintain it at an appropriate height, ensuring that the drum can be evenly stressed.

Maintenance and upkeep:

In order to ensure the continuous and stable operation of the continuous rotary vacuum filter, extend the service life of the equipment, and reduce the risk of failure, regular maintenance work should be carried out.

一、 Daily maintenance

1. Cleaning homework:

After daily equipment shutdown, promptly clean the liquid tank, drum outer wall, filter cloth/screen, and cake unloading mechanism to remove residual materials and impurities, and avoid clumping and blocking the filter medium or corroding components. When cleaning, you can choose clean water or suitable cleaning agents, and after completion, you need to dry the surface of the equipment.

2. Operation check:

During daily startup and operation, a comprehensive inspection of all components of the equipment is required

(1) Observe whether the drum runs smoothly and whether there are any abnormal vibrations or noises;

(2) Check whether the vacuum degree of the vacuum system meets the standard and whether there is any air leakage in the vacuum pipeline;

(3) Check whether the temperature of the transmission device is abnormal and whether there is any abnormal noise;

(4) Confirm whether the filter cloth/screen is intact, whether there is any damage or blockage;

(5) Check the lubrication filling of each lubrication point to ensure sufficient lubricant.

3. Lubrication management

According to the instructions, regularly supplement the lubricating parts such as bearings and gears of the transmission device with suitable lubricants, strictly control the type and amount of lubricants, and avoid excessive or insufficient wear of components.

二、 Periodic maintenance

1. Weekly maintenance:

Conduct a relatively comprehensive inspection and maintenance once a week:

Check the wear of the filter cloth/screen, and replace it promptly if it is severely worn;

Check if the blade edge of the scraper remains sharp and needs to be polished or replaced after wear and tear;

Check the oil level and quality of the vacuum pump. When the oil level is insufficient, replenish the vacuum pump oil, and replace it when the quality deteriorates;

Check the electrical control system, confirm that the sensors and instruments display normally, and that the wiring is not loose.

2. Monthly maintenance

Monthly in-depth inspection and maintenance of key components:

Check the sealing performance of the rotary drum, inspect the fan-shaped chamber for leaks, and replace the seals if there are any leaks;

Check the oil level and quality of the reducer, and add or change oil as needed;

Clean the nozzle blockage of the washing device to ensure smooth spraying;

Check and tighten all connecting bolts to prevent malfunctions caused by looseness.

3. Annual maintenance

Conduct a comprehensive dismantling inspection and maintenance once a year:

Dismantle core components such as the drum, transmission device, and vacuum system, inspect for wear and corrosion, and replace severely worn parts;

Clean the dirt and impurities inside the drum, check the uniformity of wall thickness and whether there is deformation;

Conduct comprehensive maintenance on the electrical control system, replace aging wires and electrical components;

Reassemble the equipment and debug it to ensure that all performance indicators meet the standards.

Summary:

As an efficient and continuous solid-liquid separation equipment, the continuous rotary vacuum filter an important role in industrial production with its unique working principle, qualified structure, and wide range of applications. Timely troubleshooting and regular maintenance are key to ensuring the long-term stable operation of the equipment during use. By mastering common troubleshooting methods, problems that arise during equipment operation can be quickly resolved, reducing downtime; Scientific and reasonable maintenance can effectively extend the service life of equipment and reduce operating costs.