Product Overview

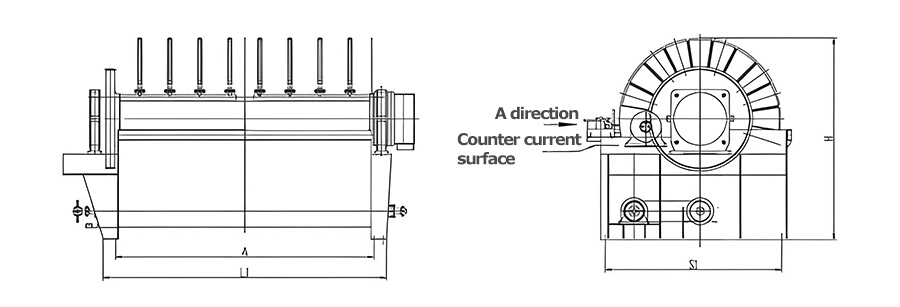

As an advanced filtration technology equipment, the core structure of Continuous rotary disk filter is constructed by several side-by-side filtration units, which are mainly annular reinforced plastic filter discs with special grooves or flute design, which skillfully enhance the filtration efficiency of the discs.

In the filtration process, the sewage from the periphery of the filter disk into the filter disk adjacent grooves and edges of each other, forming a structure similar to the rim, effectively intercepting and retaining solid impurities in the water; when entering the backwash stage, the water flow direction is reversed, from the middle of the annular filter disk to the outside flow, the process can be a strong scouring of hooks attached to the surface of the disk, and then the dirt was stripped off along with the water flow by the sewage system out of the equipment. The stripped dirt is then discharged out of the machine through the drainage system.

Thanks to its excellent filtration and self-cleaning capabilities, this equipment shows a wide range of potential applications in a variety of industrial and civil fields, such as water purification, wastewater purification, raw water pre-filtration, industrial production water filtration, and cooling water recirculation filtration.

Features and Advantages

high precision filtration

According to the diversified water standards, the filter disk can be flexibly selected, and its filtration precision covers the common range of 20μm - 200μm, and some high-quality filter disks can even reach the ultra-high precision of 5μm, which can efficiently intercept the fine particles and colloidal impurities in the water.

efficient backwashing

Backwashing time consuming very short, usually 5-20 seconds to complete the entire process, both time and water saving, and backwashing effect is significant, can quickly and fully restore the filtration efficiency of the filter disk.

fully automated operation

With fully automatic controller, with the help of time setting, flow monitoring and differential pressure sensor light signal, intelligent control of the filter unit backwash in turn, the whole process without manual operation, to ensure a continuous and stable water supply.

Durable

The filter unit is made of high-tech plastic material with excellent anti-corrosion and wear-resistant characteristics, which can greatly extend the service life of the equipment as a whole.

efficient filtration

With the ability to quickly filter, especially suitable for high-flow water treatment scenarios, to fully meet the actual needs of water treatment projects of different sizes.

low-cost maintenance

The overall structure is simple, not set up complex motors, drives and other components, while the filter disk replacement is convenient, easy and simple daily maintenance, effectively reducing maintenance costs.

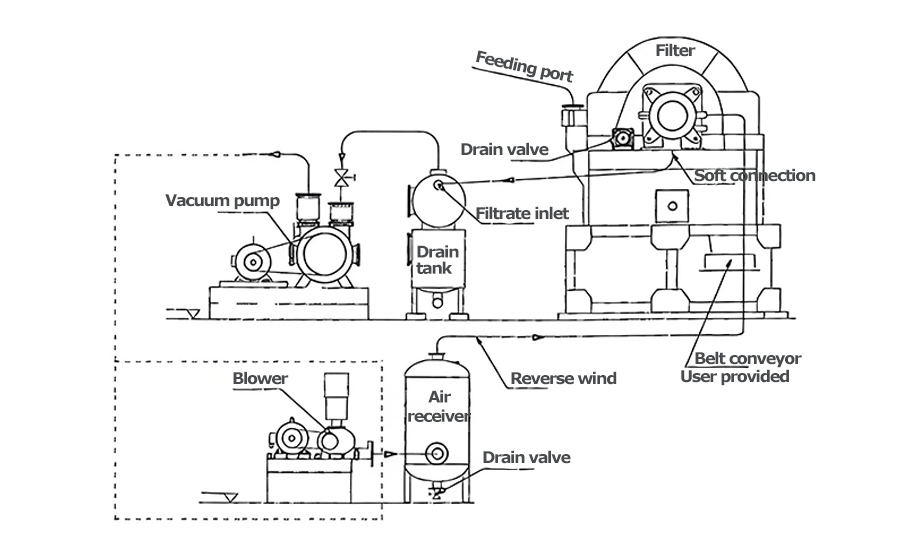

Working Principle

Filtration Process: The water to be purified flows into the rotating stock, flows into the filter disk by gravity, and penetrates from the outside to the inside, the special grooves and ribs on the filter disk form a precise filtration channel, the suspended matter with over-sized particles is retained, and the clean water enters the inside of the annular filter disk, and is led out through the outlet.

Backwashing process: the system monitors the differential pressure to meet the standard or run to the set time, automatically start backwashing. The controller regulates the valve to reverse the water flow, the backwash water pressure compresses the spring to loosen the stacked piece, and the nozzle on the cartridge pillar jets tangentially, driving the stacked piece to rotate. The clean post-filtration water is utilized to wash away the suspended matter on the surface of the filter disk to the waste water tank, and the suspended matter is eventually discharged from the filter under the effect of gravity.

Components of continuous rotary disk filter

Continuous rotary disk filter is a kind of high-efficiency filtration equipment with compact and functional design, and all components work together to realize effective filtration and purification of water.

Filter unit

As the key component of the filter, it consists of a set of shape-reinforced plastic filter disks with grooves or prismatic structure, which is responsible for completing the water filtration and impurity retention tasks.

Intelligent controller

It controls the overall operation of the filter, realizes automatic switching of filtration and backwashing processes, and can be precisely controlled according to the time, flow rate and differential pressure signals.

control valves

Including diaphragm valves and solenoid valves, used to regulate the direction of water flow and on-off state, in the filtration and backwashing process plays a key role in the control.

Monitoring instrument

Wflow meter is used for real-time monitoring of water flow data, and differential pressure signal meter is used to monitor the differential pressure between the filter inlet and outlet, so as to trigger the backwashing operation in time.

Backwashing Component

It consists of backwashing pump, nozzle and other components, which effectively removes the retained impurities with the help of clean post-filtering water for strong flushing of the filter disk.

Power drive group

Covering motor, reducer, belt or chain, etc., used to drive the filter disk to rotate, so as to realize the function of continuous filtration and backwashing.

Applications

Municipal wastewater treatment

Used in the deep treatment of municipal wastewater, efficiently removing suspended particles, colloids, bacteria and other impurities in the secondary treatment effluent, and upgrading the water quality to the reuse or discharge standard.

Industrial wastewater treatment

In the wastewater treatment of paper making, printing and dyeing, chemical industry, pharmaceutical industry, etc., to remove organic matter, heavy metal ions, suspended solids, etc., to achieve discharge or reuse, saving water resources.

Circulating water optimization

In industrial circulating cooling water, landscape water circulation and other systems, removing suspended solids and microorganisms in the water, preventing pipeline clogging and equipment corrosion, and improving the utilization rate of circulating water.

Seawater desalination pre-treatment

Responsible for seawater desalination pre-treatment, removing suspended particles, organic matter and microorganisms in seawater, providing high-quality feed water for the subsequent reverse osmosis process, and prolonging the life of the equipment.

Continuous Rotary Disk Filter Manufacturer

In the manufacturing process of Continuous Rotary Disk Filter, YiNuo Machinery adheres to strict quality standards, from the careful selection of raw materials, to the strict control of each process in the production link, and to the finished product many times before the factory test, each step of which condenses YiNuo Mechanical Team's persistent pursuit of quality, to ensure that each and every filter delivered to the hands of the customer has outstanding performance and reliable and stable quality. Each filter delivered to customers has excellent performance and reliable and stable quality.

In the field of after-sales service, YNM has a professional and responsive after-sales team. When customers encounter equipment operation questions, fault maintenance and other issues, the after-sales team can give professional answers and solutions in a short time. So that customers can Europe can rest assured, worry-free contact continuous rotary disk filter, optimize their own production processes and water treatment work.

Hot Tags: