Ceramic vacuum filter Product Overview

Ceramic vacuum filter, as an innovative solid-liquid separation device, it adopts the vacuum negative pressure drive and the unique adsorption performance of ceramic crawler plate, which cleverly utilizes the strong driving force generated by the vacuum negative pressure, combined with the excellent adsorption performance of ceramic liner plate itself, to achieve high efficiency, energy-saving, environmentally friendly effect in the solid-liquid separation operation, and it is widely used in the fields of mining, chemical industry, environmental protection and so on, Environmental protection and other fields, is the ideal choice to replace the traditional filtration equipment.

The Ceramic vacuum filter is designed to place several filter discs equipped with ceramic filter plates in the slurry, and utilize the negative pressure generated by the vacuum system, so that the liquid in the slurry is pumped away through the micropores of the ceramic filter plates, while the solid particles are retained to form the cake, which is then blown back or scraped to achieve the shedding of the cake. Its core advantage lies in the wear-resistant and corrosion-resistant characteristics of the ceramic filter plate as well as its highly efficient dewatering ability, which can significantly reduce the subsequent drying costs and reduce wastewater discharge.

Core Advantages

Special filter media

Ceramic filter plate has super chemical stability, can withstand the erosion of acid and alkali environment, and is very wear-resistant. Its service life is up to 3-5 years, compared with the traditional filter cloth only 3-6 months of use cycle, the advantage is significant.

Dewatering effect is good

After the treatment of the equipment, the water content of the filter cake to deal with the lower level, lower than ordinary vacuum filter 5-15%, can reduce the subsequent drying link of energy consumption to a greater extent.

High level of automation

The equipment is equipped with advanced PLC control system, which can realize automatic operation of the whole process of filtration, cleaning, unloading, etc., effectively reduce the participation of manpower and improve the production efficiency and stability.

Outstanding environmental performance

Filtrate recovery rate of up to 95% or more, can Europe to achieve the recycling of filtrate reuse, a substantial reduction in wastewater discharges, and does not require the use of filter cloth, reducing the amount of solid-liquid waste generation.

Product Model

| Model | Filtering area (㎡) | Number of filter discs (pcs) | Processing capacity (t/h) | Vacuum degree (MPa) | Power (kW) | Overall dimensions (length × width × height, m) |

| TC-10 | 10 | 2 | 1-3 | -0.06~-0.09 | 5.5 | 3.2×1.8×2.1 |

| TC-30 | 30 | 4 | 3-8 | -0.06~-0.09 | 11 | 4.5×2.2×2.5 |

| TC-50 | 50 | 6 | 8-15 | -0.06~-0.09 | 15 | 5.8×2.5×2.8 |

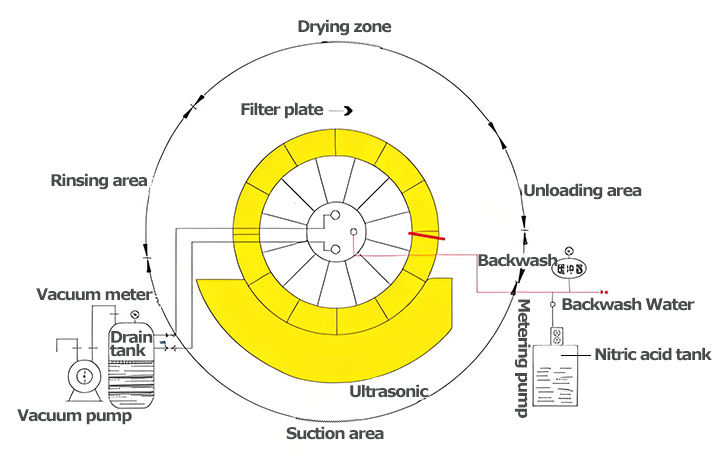

Structure

Ceramic vacuum filter has a delicate structure and complete functions, and its core structure mainly consists of: filter disc, vacuum system, stirring system, cleaning system, discharging device and automatic control system. Among them, the ceramic filter plate is called the core component, which has a uniformly distributed microporous structure, the pore size is generally between 0.1-5μm, which can realize high-efficiency filtration and has excellent adsorption function.

Workflow

Ceramic Vacuum Disc Filter runs in an orderly manner, and its workflow can be precisely divided into three key stages

Adsorption stage

The filter disc is slowly immersed into the slurry, and the vacuum device is randomly turned on. Under negative pressure, the liquid in the slurry quickly passes through the ceramic filter plate, and is sucked into the vacuum pipeline, while the solid particles are gradually piled up on the surface of the aluminum plate to form the filter cake.

Drying stage

After the filter plate is turned out of the filter surface, the vacuum system continues to play a role in further pumping the residual moisture in the filter cake, so that the cake has a higher degree of dewatering and the moisture content is significantly reduced.

Unloading stage

The blowback system is activated, the compressed air is passed into the aluminum plate, the strong airflow will completely blow down the filter cake from the aluminum plate, at the same time, the cleaning system is opened, the surface of the filter plate is comprehensively rinsed, effectively preventing the filter holes from being clogged, and ensuring the normal operation of the equipment in the future.

Applications:

Ceramic disc filter is a suitable equipment for processing fine particles and high viscosity slurry.

| Industry | Specific applications | Example of material handling |

| Mining industry | Dehydration of metallic ores (copper, iron, zinc) and non-metallic ores | Iron concentrate, zinc concentrate, graphite, quartz sand |

| Chemical industry | Separation and purification of chemical products | Calcium carbonate, barium sulfate, catalyst |

| Environment protection | Industrial wastewater and sludge dewatering | Municipal sewage sludge, electroplating wastewater sludge |

| Food and Medicine | Fine material filtration | Starch,pharmaceuticalintermediates |

Ceramic vacuum filter Price

The price of ceramic disk filter is not a single value, but a combination of “equipment specifications + customized needs + long-term value”. When we choose equipment, we need to jump out of the “only look at the initial offer” of the misunderstanding, should be combined with the characteristics of the material, capacity needs and long-term operating costs to calculate the cost-effective.

Also need to consider the manufacturer's after-sales service, high-quality after-sales service can be a solution for enterprises to worry about, to ensure that equipment failure in the operation process can be timely and effective maintenance and processing. A manufacturer with a perfect after-sales service system, can provide enterprises with a safe direction of the technical protection, so that the equipment is always in good operating condition, thus creating greater value for the enterprise.

Hot Tags: