As a solid-liquid separation equipment integrating vacuum negative pressure adsorption and continuous conveying technology of annular conveyor belt, Horizontal belt filter upgrades the traditional filtration operation into a stable and efficient continuous production mode through the design of automated process. With accurate parameter control, reliable separation performance and intelligent operation cross-section, this equipment has become the core equipment for solid-liquid separation process optimization in the fields of environmental protection, chemical industry, metallurgy, food and so on.

Core Advantages

The unique performance of the Horizontal belt filter stems from its innovative structural design and dynamic filtration mechanism, which is mainly reflected in the following technical characteristics:

Full process operation

Relying on the closed-loop circulatory system of the ring-shaped crawler belt, it realizes the uninterrupted continuous operation of fabric, filtration, washing, dewatering and unloading, which perfectly matches the demand of industrialized large-scale production.

Intelligent parameter control

Integrated PLC automatic control system can adjust the key parameters such as the running speed of filter belt, vacuum adsorption strength, feed flow rate, etc., to ensure the process stability and reduce the dependence on manpower.

Accurate filter cake control

Through dynamic balance of the filter belt moving rate and vacuum negative pressure value, can be customized to control the range of filter cake thickness and final water content.

Multi-material adaptability

Support the rapid replacement of the filter belt material and flexible switching of washing mode, easy to deal with strong corrosion, high viscosity, easy to oxidize and other special slurries.

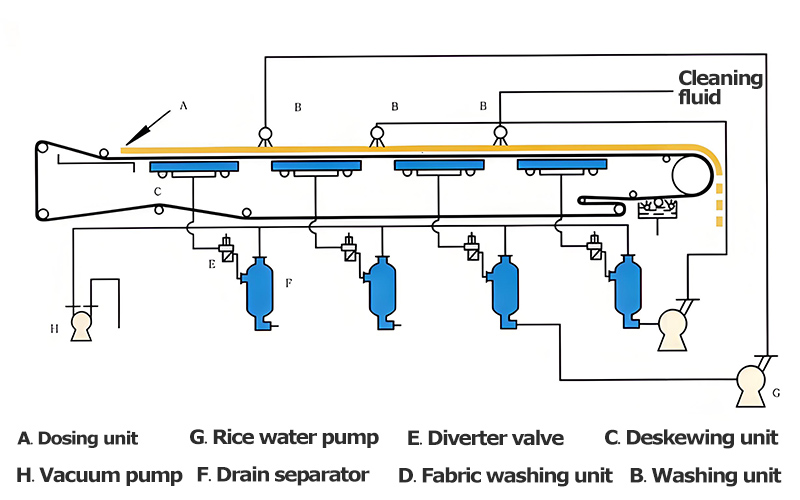

Structure

Horizontal belt filter has a precise structure and clear division of labor, each missing to ensure that the filtration process is continuous and stable, the specific composition and role of the following table:

| Core component | Primary role |

| Rackmount | Support the whole equipment to ensure the installation precision and stability of each component |

| Vacuum chamber | Generates and maintains a vacuum environment, which is the core power source for solid-liquid separation |

| Ring filter belt | Carries slurry and acts as a filter medium, allowing liquid to pass through and retaining solid particles, with materials selected according to slurry characteristics. |

| Transmission system | Drive the filter belt and conveyor belt at a constant speed to control the filtration speed and production rhythm. |

| Feeder | Distribute the slurry evenly on the filter belt to ensure that the filter area is fully utilized. |

| Washing device | Spray washing of the filter cake (if required) to reduce soluble impurities in the filter cake |

| Unloading Device | StrippingthedewateredcakefromthefilterbeltCompletesthefinalstepofthefiltrationcycle. |

Working Principle

Four steps to complete high-efficiency continuous filtration

Horizontal vacuum belt filter with “continuous operation” and “vacuum suction” as the core design concept, its complete workflow can be divided into the following four key links:

Uniform fabric stage

The slurry is evenly spread on the surface of the circulating moving filter belt through the special feeding system, and the filter belt enters the vacuum adsorption area smoothly with the transmission device.

Vacuum solid-liquid separation stage

Driven by the negative pressure generated by the vacuum box, the liquid phase in the slurry quickly passes through the filtering cloth to enter the liquid collection cavity, and the solid phase particles are retained and compacted to form a dense filter cake.

Depth purification and dewatering stage

When the purity of the filter cake is needed to be improved When it is necessary to improve the purity of the filter cake, the washing system sprays the cleaning liquid, realizes the impurity replacement under the action of vacuum, and then the filter cake enters into the high-pressure dewatering area, and further reduces the moisture content through mechanical extrusion.

Automatic unloading and filter belt regeneration stage

When the filter belt carrying the filter cake runs to the unloading roller, it realizes solid-phase stripping through the scraper or blowback device, and then the filter belt goes through the washing and spraying system to remove the residual particles, and then re-enters to complete the closed-loop cycle.

Application

The versatility of Horizontal vacuum filter makes them widely used in a number of industries

Chemical industry

Dyestuff intermediate filtration, fertilizer slurry dewatering, catalyst recovery.

Food industry

Starch slurry filtration, fruit juice clarification, solid-liquid separation in the processing of dairy products.

Environmental protection industry

Sludge dewatering in wastewater treatment, pre-treatment of industrial wastewater reuse money.

Pharmaceutical industry

Pharmaceutical industry: pharmaceutical intermediates filtration, fermentation liquid separation.

Application value

For enterprise production to create more efficiency space

Vacuum belt filter practice application can be from the efficiency, cost, quality, environmental protection and operation and maintenance of the five major levels for the enterprise to bring significant benefits, specific performance:

Enhance production efficiency

Through the whole process of continuous operation mode, eliminating the loading and unloading stagnation time of traditional intermittent filtration, the single-day processing capacity can be increased by 150%-200% compared with the traditional equipment, which significantly shortens the production cycle.

01

Lower labor cost

PLC intelligent control system realizes the automatic operation of the whole process of feeding, dewatering and unloading, and each production line can reduce 3-5 field operators and reduce the error of manual intervention.

02

Guarantee product quality

Dynamic vacuum adjustment system and frequency conversion filter belt drive technology work together to control the fluctuation range of water content of filter cake within ±1.5%, providing stable raw materials for downstream processes.

03

Resource recycling

The graded washing system supports the filtrate recycling, the recycling rate of clean water can reach more than 85%, and the water consumption of a single ton of product can be reduced by 40%-60%, which eases the pressure of environmental protection treatment.

04

Operation and maintenance cost reduction

The use of high-strength composite filter belt and self-cleaning spray device, filter belt replacement cycle extended to 4-8 months, the comprehensive failure rate of equipment down to less than 2%.

05

Horizontal belt filter Manufacturer

Vacuum Belt Filter has successfully cracked the industry pain points of traditional solid-liquid separation equipment in terms of capacity efficiency, operation complexity and product consistency by virtue of the trinity of technology structure of "continuous operation system + intelligent regulation system + millimeter-level process control". Through the synergistic innovation of vacuum adsorption and dynamic conveying, it builds up a new paradigm of "high efficiency, stability and economy" separation in chemical refining, mining and metallurgy, environmental protection treatment and other heavy industry scenarios. The core competitive value of the equipment is to transform the mechanical design advantages into quantifiable production indicators: single-line capacity increased by 200% at the same time, the fluctuation of the water content of the cake will be controlled within ± 1%, and through the modular design to achieve the rapid adaptation of different material conditions, becoming a benchmark equipment choice for the modern industry to move towards intelligent, green production.

Hot Tags: