Rotary vacuum disc filter is an important equipment of continuous filter, which plays a key role in the field of solid-liquid separation. Its construction has similarities with rotary vacuum filter and the operation principle is basically the same. Through unique design, this equipment can efficiently sight the separation of solid particles and liquid in suspension, and is widely used in many industries.

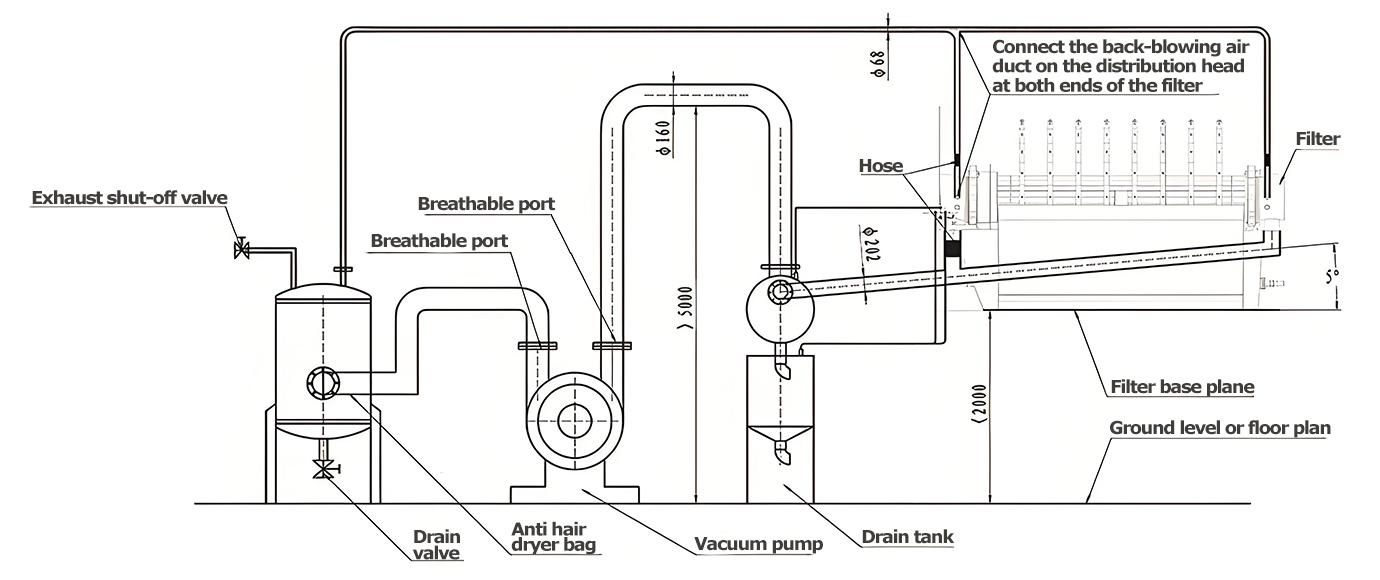

The core mechanism of solid-liquid separation in the sight of rotary vacuum disc filter lies in the ingenious use of vacuum tube suction to drive the filtration process. Its filter disc will be in the slurry tank at a constant and relatively slow rate of circular rotation, while the vacuum pump starts to work, in the filtration cut-off to the two ends to create a significant difference in the pressure environment, the formation of a stable pressure difference.

Under the strong effect of this pressure difference, the solid particles in the slurry are rapidly and closely adsorbed on the filter cloth covering the surface of the filter disk. As the adsorption process continues to advance, the solid particles continue to accumulate, gather, and gradually form a layer of uniform thickness and relatively dense structure of the filter cake.

And the filtrate by virtue of its own good mobility, driven by the pressure difference, in turn, through the porous channels within the cake and the fine pores of the filter cloth, and ultimately along the pre-determined path from the center axis smoothly discharged, to achieve the effect of preliminary separation of solids and liquids.

When the filter cake accumulates to the preset thickness, the scraper cuts in at a specific angle and strength to precisely strip the filter cake from the surface of the disk. At the same time, the wind generated by the blower with a certain pressure and flow rate forms a strong boosting force, which works in concert with the scraper to blow the stripped filter cake down to the filter cake unloading tank, thus a complete filtration cycle is successfully completed.

Product Advantages

High-efficiency filtration

Relying on the strong adsorption force of the vacuum tube and the scientific and reasonable structural layout, the product can quickly and efficiently complete the solid-liquid separation task, significantly improve the production efficiency, while effectively cutting production costs, creating greater value for the enterprise.

Material Adaptability

With excellent compatibility, it can easily cope with all kinds of different characteristics of material processing needs. Whether it is fine particles or complex materials mixed with sludge, it can achieve excellent filtration results to meet diversified production scenarios.

Stable and reliable

After optimized design, the mixing, transmission and other key systems of the equipment operate smoothly and reliably, which greatly reduces the chance of failure and ensures that the production process can be carried out in a continuous and stable manner, escorting the production of the enterprise.

Energy saving and environmental protection

In the operation process, the product has relatively low energy consumption, which positively responds to the green development concept of energy saving and consumption reduction of modern enterprises. By reducing energy consumption, it effectively reduces the enterprise's energy cost expenditure and helps the enterprise to realize a win-win situation in terms of economic and environmental benefits.

Product application

Mining field

Vacuum Disc Filter is a “dewatering tool” for processing fine-grained materials in mining industry, especially good at processing fine-grained concentrates containing sludge. In copper, lead, zinc and other non-ferrous metal ore dressing, it can quickly and efficiently remove the moisture of the concentrate, improve the quality of the concentrate, safeguard the subsequent processing and transportation, for the funny use of non-ferrous metals to build a solid foundation.

Chemical industry

In the chemical industry, this equipment is a better choice for suspension separation and product purification, when pharmaceuticals, precise separation of impurities in the liquid, to ensure the safety and effectiveness of drugs; fertilizer production, the efficient completion of the solid-liquid separation, so that the composition of fertilizer uniformity, fertilizer efficiency to enhance the reduction of production costs and waste.

Environmental protection field

It can effectively deal with all kinds of wastewater, reduce material loss and environmental pollution, in the city wastewater, calcium carbide wastewater, paper wastewater, steel rolling wastewater, chemical fiber wastewater and black water treatment of media slurry and other aspects of the performance, help improve water quality and environmental protection cause development.

Metallurgical industry

In the smelting process of iron and steel, aluminum and other metals, Vacuum Disc Filter is a “key role” to ensure production. For example, in alumina plant, it can separate solid particles in alumina slurry in time, recover water, improve resource utilization and ensure smooth production.

Maintenance

Regular inspection

In accordance with the cycle of the various components of the equipment to carry out inspections, covering the filter cloth, filter plate, mixing device and transmission system, etc., to see whether there are signs of wear and tear, damage, and once found in time to deal with.

01

Filter cloth maintenance

Filter cloth as the core component of the filter, need to be cleaned regularly to avoid clogging and affect the filtering performance. If the filter cloth is damaged, replace it immediately. Equipped with automatic cleaning device equipment, to ensure that the normal operation of the device.

02

lubrication and maintenance

Regularly add appropriate lubricant or grease for the transmission parts of the equipment, bearings, etc., to reduce the friction between the parts, in order to extend the service life of the equipment.

03

Equipment cleaning

Regular cleaning of the equipment body and the surrounding environment, to prevent material residues and dust accumulation, to ensure the normal operation of the equipment, to create a good working environment.

04

Wearing parts update

According to the use of equipment, in advance to prepare the scraper, seals and other wearing parts, to be its service life or damage, timely replacement, to ensure stable operation of equipment.

05

Service support

Pre-sale service

Senior technical team to provide detailed consultation, relying on customer production demand and material characteristics, accurate recommendation of vacuum disc filter models, customized technical solutions and give a quote.

In-sale service

Guarantee the delivery of equipment on time and with high quality, assist in installation and commissioning, and help operators familiarize themselves with the precautions to be taken in the operation of the equipment.

After-sales service

Build a perfect system, provide technical support 24 hours a day, respond quickly when the equipment fails, have professional personnel to communicate with you to assist in maintenance, regular visits to collect feedback to optimize products and services.

Rotary Vacuum Disc Filter Manufacturer

As a professional solid-liquid separation equipment, the purchase of Rotary Vacuum Disc Filter cannot be separated from the comprehensive consideration of the manufacturer. At present, there are many enterprises with rich experience and technical strength in the market, which provide customized equipment solutions for different industries by virtue of mature production technology, strict quality control and perfect after-sales service system. These manufacturers can not only ensure stable performance and efficient operation of the equipment, but also according to the customer's specific production needs, the equipment for targeted optimization, to ensure that the equipment and production scenarios a high degree of adaptability.

For the procurement needs of enterprises, it is recommended to fully define their production needs on the basis of more communication with the manufacturer, a detailed understanding of the parameters of the equipment, performance, after-sales service and price, etc., after a comprehensive comparison of the selection of more cost-effective cooperation programs to achieve a balance between production efficiency and cost control.

Hot Tags: